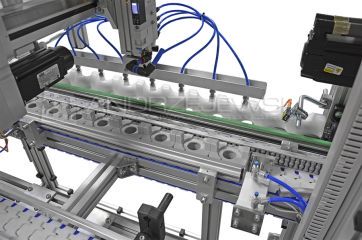

Assembly line is usually composed of a transporter or a set of transporters, assembly stations, robots and manipulators, as well as workplace auxiliary devices.

Our company has vast experience in the construction of semi-automatic assembly lines, i.e. such in which many procedures are performed by workers at particular work stations, and the work place is determined by a transporter or a set of transporters coupled with a relevant control system. Depending on the designated task, a transport course is established which exacts the line's work pace, and assembly stations (versatile or dedicated for each procedure to be performed on it) are built on to it. When necessary, the stations are equipped with specially designed support devices. These can be relevant slots for setting the assembled component in the proper position (poka yoke), presses facilitating the composition of components into whole, various dispensers, etc.

Our company has vast experience in the construction of semi-automatic assembly lines, i.e. such in which many procedures are performed by workers at particular work stations, and the work place is determined by a transporter or a set of transporters coupled with a relevant control system. Depending on the designated task, a transport course is established which exacts the line's work pace, and assembly stations (versatile or dedicated for each procedure to be performed on it) are built on to it. When necessary, the stations are equipped with specially designed support devices. These can be relevant slots for setting the assembled component in the proper position (poka yoke), presses facilitating the composition of components into whole, various dispensers, etc.

| If the assembly is carried out on special pallets or assembly fixtures, it is also necessary to perform a pallet circulation track. Depending on the space available for the investor for setting up the line, and taking into account the times of operation on individual stations, the assembly lines can be constructed as simple lines or as L- or U-shape. If auxiliary operations are present, component assembly stations or slots may be located near the line. Our specialists have vast experience in the construction of such systems. Based on the data presented by the investor regarding the type of product, technology of its assembly and possible detailed requirements, we can suggest a comprehensive solution. |